Industry Background: Growing FGD Demand Driven by Environmental Regulations

With increasingly strict global environmental regulations, industries such as coal-fired power generation, steel production, and chemical manufacturing are under pressure to adopt effective flue gas desulfurization (FGD) technologies. The main goal of FGD is to remove sulfur dioxide (SO₂) and other harmful particulates from flue gas emissions to meet legal standards.

Among the various FGD techniques, wet desulfurization is widely adopted. One core component is the belt filter press. The desulfurization filter belt greatly impacts both efficiency and operating costs.

Case Study: Bolian Belt Filter Cloth in a Coal-Fired Power Plant

1. Customer Challenges

A large coal-fired power plant using a wet FGD system faced several issues with its existing filter cloth:

Short service life: The harsh environment of high temperature and strong chemical exposure caused the filter belt to corrode and deform, requiring replacement every 3 months.

Low filtration efficiency: Gypsum particles in the slurry frequently clogged the filter media, reducing desulfurization effectiveness and causing emission standards to be exceeded.

High operational costs: Frequent replacements led to increased maintenance downtime.

2. Bolian Desulfurization Filter Belt Solution

The plant adopted Bolian’s polyester monofilament filter cloth, which offers several advantages:

High temperature and chemical resistance: Made from PET material, it withstands harsh acidic and alkaline environments, with a service life 6 months and more.

High filtration precision: Optimized weaving technology ensures effective gypsum particle capture while maintaining excellent airflow for improved FGD performance.

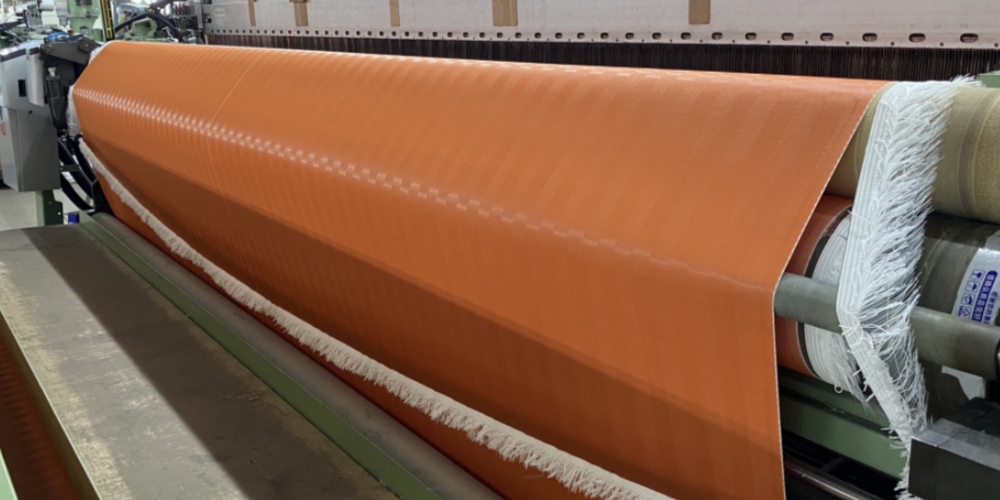

Superior tensile strength: Manufactured using heavy-duty looms, the filter belt can reach widths of up to 3.9 meters, making it ideal for large belt filters and ensuring stable operation.

Calendered and sealed edges: Special finishing reduces edge wear and fraying, minimizing maintenance needs.

3. Application Results

Enhanced Desulfurization Efficiency: Effective filtration of gypsum slurry met environmental standards.

Lower Operational Costs: Extended replacement cycle and reduced maintenance frequency saved time and money.

Minimized Downtime: Excellent anti-clogging properties reduced cleaning frequency and ensured continuous operation.

Conclusion: The Critical Role of Desulfurization Filter Belts

Bolian’s desulfurization filter belts—with their chemical resistance, filtration efficiency, and long service life—have become a reliable solution for flue gas treatment in power plants, steel mills, and chemical plants. Looking ahead, high-performance filter materials will play an increasingly vital role in industrial desulfurization, wastewater treatment, and solid waste recovery.

Tessuto filtrante Bolian

Tessuto filtrante Bolian