Dust Filter bags are essential filtration materials in industrial dust collection and flue gas purification. According to different operating temperatures, normal temperature filter bags, medium temperature filter bags, and high temperature filter bags each have unique performance characteristics and application fields.

Dust Filter bags are essential filtration materials in industrial dust collection and flue gas purification. According to different operating temperatures, normal temperature filter bags, medium temperature filter bags, and high temperature filter bags each have unique performance characteristics and application fields.

Three Types of Dust Bags

Normal Temperature Filter Bags

Manufacturers design normal temperature filter bags to filter flue gas under standard temperature conditions. They feature excellent air permeability and chemical resistance. These characteristics make them widely used in metallurgy, building materials, chemical, and power industries for dust control and gas purification.

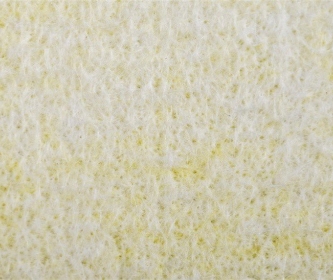

The most common material is polyester needle felt, which offers high porosity, good air permeability, and strong resistance to chemical corrosion. Polyester normal temperature filter bags often receive treatments such as singeing, calendering, water and oil repellency, PTFE impregnation, coating, or membrane lamination. These processes further enhance their performance.

These treatments significantly improve chemical stability, prevent condensation, enhance dust release, extend service life, and ensure that emission standards are met.

Medium Temperature Filter Bags

When the operating conditions exceed normal temperature ranges, medium temperature dust filter bags are required. Manufacturers mainly make these dust collection bags from aramid fibers and PPS fibers, materials known for their excellent heat resistance and chemical stability.

Medium temperature dust collection bags undergo special treatments such as water repellency, oil resistance, anti-corrosion, and impregnation, allowing them to withstand harsh operating environments. Industries such as steel, chemical processing, and smelting widely use them, where elevated temperatures and corrosive gases are present.

High Temperature Filter Bags

For high-temperature working conditions, such as cement kilns, coal-fired boilers, and waste incinerators, high temperature dust collection bags are the optimal choice. They are typically manufactured from P84 fibers, expanded glass fibers, or ultra-fine glass fibers.

These materials provide excellent thermal stability, a wide temperature resistance range, high filtration efficiency, and long service life. High temperature dust collection bags maintain their strength and stability even under extreme conditions. They effectively reduce emissions, and help achieve both environmental protection and energy-saving goals.

Conclusion

Engineers select normal, medium, and high temperature filter bags based on specific process conditions. Choosing the right filter material and treatment can greatly enhance the efficiency and durability of dust collection systems. Proper selection and maintenance of dust collection bags ensure compliance with environmental regulations. They also reduce operating costs and improve the overall sustainability of industrial production.