In the highly competitive mining industry, optimizing each production step can bring significant advantages. Filter presses play a critical role in tailings and concentrate dewatering, and the filter cloth—being the core filtration medium—directly determines filtration efficiency and operational stability.

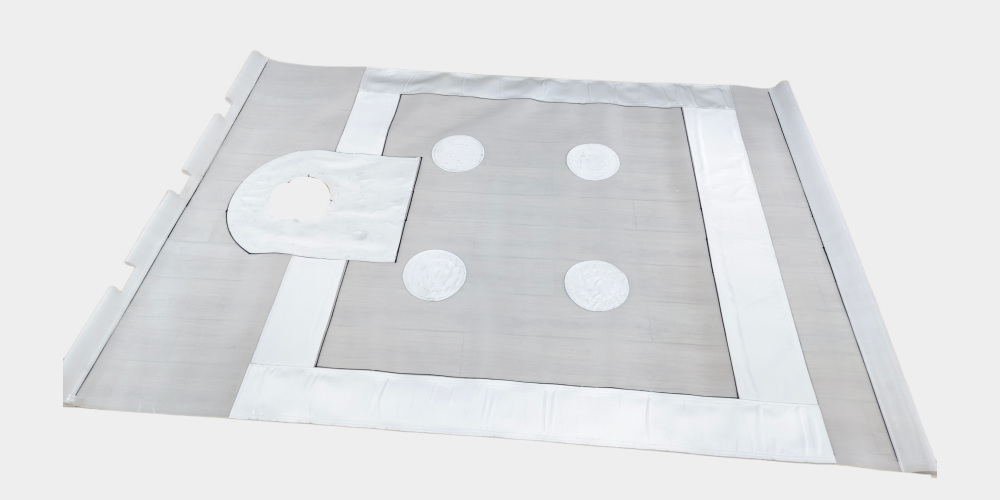

This case study presents how a 1.58m x 2.27m polypropylene (PP) plate & frame filter cloth helped a client achieve efficient solid-liquid separation in iron ore processing.

I. Solution: Why Choose Polypropylene Filter Cloth?

After thoroughly understanding the client’s requirements and working environment, Bolian’s technical team recommended a tailor-made polypropylene (PP) press filter cloth. The decision was based on the following advantages:

- Excellent wear and chemical resistance

Polypropylene fibers provide strong resistance to acids, alkalis, and corrosive substances, making them suitable for complex iron ore slurry conditions. With outstanding wear resistance, the cloth maintains stable performance under demanding conditions, extending service life. - Smooth surface for easy cake release

The naturally smooth PP surface, combined with calendering treatment, makes cake discharge much easier. This improves productivity while reducing manual cleaning and downtime. - Stable filtration efficiency

We provided a customized filter cloth with precise dimensions (1.58m x 2.27m) to perfectly fit the client’s filter plates. The optimized weaving structure ensured consistent pore distribution, achieving high water permeability and reliable separation performance.

II. Application Results

Field application results showed that the polypropylene press filter cloth delivered excellent performance:

Significantly reduced cake moisture, achieving ideal dewatering results;

Longer lifespan compared with previous products, reducing replacement frequency;

More stable equipment operation, lowering maintenance costs and minimizing downtime.

III. Conclusion

Selecting the right filter cloth not only solves immediate process challenges but also drives long-term cost savings and efficiency gains. With its durability, chemical resistance, easy cake release, and high filtration performance, polypropylene plate & frame filter cloth is an ideal solution for solid-liquid separation in the iron ore industry.

If you are facing similar challenges with filtration efficiency or operational costs, this could be the turning point. Contact Bolian today to get a tailored filtration solution for your process!