The Role of Hydraulic Oil Filters in System Performance

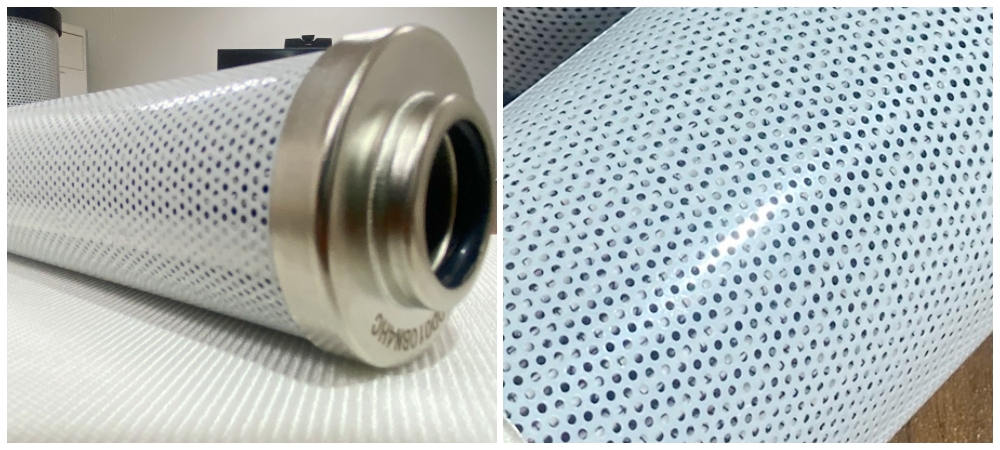

During long-term hydraulic system operation, the hydraulic oil filter element plays a critical role in filtering impurities and protecting key components. The condition and service life of the filter directly affect the efficiency and reliability of the entire system. Therefore, mastering the correct replacement method and key precautions is essential. The following guide provides practical steps to help you replace hydraulic oil filters correctly.

Inspect Filters and Diagnose System Conditions Before Replacement

Before replacing the hydraulic oil filter, drain the old hydraulic oil from the tank and carefully inspect the three types of filters—return filter, suction filter, and pilot filter. Check for iron filings, copper chips, or other foreign particles. If such contaminants are found, it may indicate internal wear or malfunction of hydraulic components. In this case, stop the replacement process, repair the faulty parts, and clean the system thoroughly before installing new filters.

Replace All Hydraulic Oil Filters at the Same Time

When replacing hydraulic oil, make sure to replace all types of hydraulic oil filters at the same time, including the return, suction, and pilot filters. Otherwise, the replacement effect will be significantly reduced. Additionally, avoid mixing different grades or brands of hydraulic oil, as doing so may cause filter reactions and form flocculent precipitates.

Install Filter Before Adding New Hydraulic Oil

Before adding new hydraulic oil, ensure that the hydraulic oil filter—especially the suction filter—are installed first. The port covered by the suction filter is directly connected to the main pump, and if impurities accidentally enter, it may cause accelerated pump wear or even severe pump damage.

Fully Vent the Main Pump After Oil Refill

After adding new hydraulic oil, make sure fully vent the main pump.. Air remaining inside may cause vehicle inaction or abnormal pump noise. To vent the system, loosen the pipe joint at the top of the pump and fill it directly with hydraulic oil. Regularly monitor oil condition, and replace the filter immediately once clogging occurs, as it is a consumable part.

Clean the Hydraulic System and Prevent Secondary Contamination

When replacing hydraulic oil filters, clean the system oil tank and pipelines thoroughly. Use oil-filling equipment equipped with filters to avoid secondary contamination. Prevent hydraulic oil in the tank from prolonged direct contact with air, and never mix new and old oil. These practices help extend the service life of hydraulic oil filters and maintain system stability.